Coastal construction projects are continually exposed to harsh environmental conditions such as saltwater, humidity, and strong winds, making the selection of materials a critical component of their success. Among these materials, marine-grade castings play a significant role in enhancing the durability and longevity of structures built in these demanding environments.

Understanding Marine-Grade Castings

Marine-grade castings are specifically engineered to withstand the corrosive nature of marine environments. These castings are made from materials that offer exceptional resistance to rust and deterioration, two common issues faced in coastal areas. The utilisation of such castings in construction projects helps in maintaining structural integrity over prolonged periods.

Materials Used in Marine-Grade Castings

Materials often chosen for marine-grade castings include stainless steel, aluminium, and certain types of bronze. Each material offers unique properties that make it suitable for specific applications. Stainless steel is favoured for its corrosion resistance and strength, while aluminium is chosen for its lightweight nature and ability to resist oxidation. Bronze, particularly aluminium bronze, is known for its durability and excellent resistance to seawater corrosion.

The Role of Engineered Casting Solutions

Implementing engineered casting solutions for coastal projects is a prudent strategy to ensure the longevity and functionality of structures. Engineered solutions involve customising the casting materials and processes to match the specific demands of a project. This bespoke approach guarantees that every aspect of the casting’s performance is optimised for the environment it will encounter.

Benefits of Using Marine-Grade Castings

There are several advantages associated with the use of marine-grade castings in construction. Firstly, they provide enhanced corrosion resistance, which is vital for coastal infrastructure. Secondly, these castings are designed to endure extreme weather conditions, which are frequent in oceanic regions. Lastly, they contribute to reduced maintenance costs over time, as their inherent resilience lessens the need for repairs and replacements.

Applications in Coastal Infrastructure

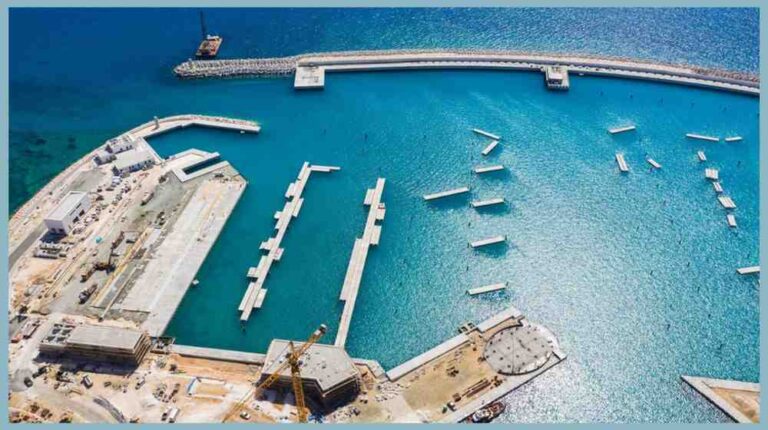

Marine-grade castings are utilised in a variety of coastal infrastructure projects. Common applications include bridges, seawalls, jetties, and piers. Wherever exposure to seawater and marine environments is a factor, these castings can significantly improve the durability and safety of the structures.

Innovations in Casting Technology

Advancements in casting technologies have further refined the effectiveness of marine-grade materials. Modern techniques such as computer-aided design (CAD) and 3D printing in casting processes allow for more precise and efficient production of cast components. These innovations contribute to better quality control and improved performance metrics in challenging environments.

The Importance of Quality Control

Quality control in the production of marine-grade castings is paramount. Rigorous testing and adherence to industry standards ensure that these components can withstand the rigorous demands placed upon them. By focussing on quality throughout the production process, manufacturers can deliver castings that meet the specific needs of coastal projects.

Choosing the Right Casting Solutions Provider

Selecting a reliable provider like FC Casting Solutions is crucial for project success. A reputable provider offers both the expertise and the technological capabilities needed to produce high-quality marine-grade castings tailored to specific project requirements.

Environmental Considerations

With the growing emphasis on sustainability, using environmentally friendly materials in marine-grade castings is becoming increasingly important. By selecting sustainable materials and processes, construction projects can minimise their environmental impact while still achieving the desired durability and resilience.

Cost Implications of Marine-Grade Castings

While the initial cost of marine-grade castings might be higher than standard materials, the long-term savings are significant. Reduced maintenance, fewer repairs, and extended service life contribute to overall cost-effectiveness, making these castings a wise investment for any coastal construction endeavour.

Challenges in Coastal Construction

Despite the benefits, the implementation of marine-grade castings faces challenges such as proper material selection, customisation to specific environmental conditions, and ensuring adequate quality control measures. Overcoming these challenges demands expertise and experience, which underlines the importance of working with seasoned professionals in the field.

Future Trends in Marine-Grade Castings

Looking ahead, the field of marine-grade castings is expected to continue evolving with new materials and technologies. Research into novel alloys and the integration of nanotechnology in casting processes promise to further enhance the properties of these materials, ensuring even greater resistance to corrosion and damage.

Conclusion

Marine-grade castings are indispensable in enhancing the durability of coastal construction projects. Their ability to withstand harsh marine environments makes them an essential component in ensuring the longevity and safety of structures exposed to such conditions. With a focus on innovation and quality, FC Casting Solutions remains at the forefront of delivering reliable and effective casting solutions for the future of coastal infrastructure.