Manufacturers in industries like food, beverage, cosmetics, and chemicals all face the same challenge: how to fill containers quickly, accurately, and with minimal waste. Relying on manual or outdated equipment often leads to inconsistent fills, slower production rates, and higher operating costs. That’s where the piston filler comes in. Designed to deliver speed, consistency, and reliability, this technology is a smart investment for businesses that want to boost throughput while maintaining product quality. By adopting piston filling machines, companies streamline operations and set the stage for scalable, long-term growth.

What Is a Piston Filler?

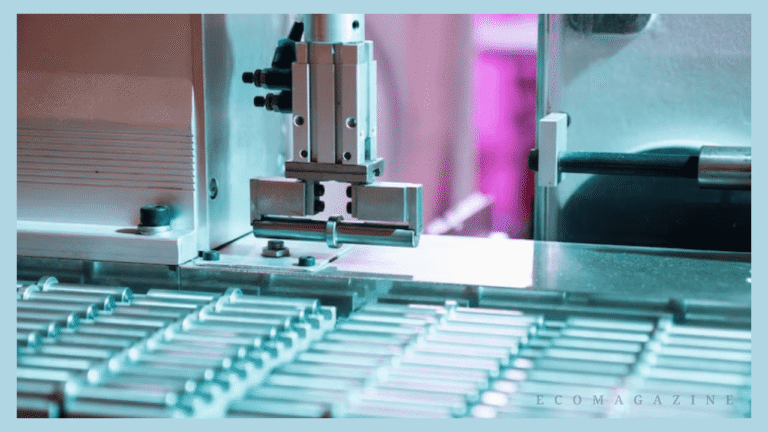

A piston filling machine works by drawing product into a cylinder with a piston and then dispensing it into containers with an exact volume each cycle. This makes it especially effective for liquids, semi-liquids, and even thick products like sauces, creams, or gels. Unlike some filling machines that struggle with viscosity, a piston machine maintains accuracy across a wide range of product types. Piston fillers are available as manual, semi-automatic, and fully automatic piston filling machines, giving manufacturers flexibility depending on their production needs. For operations looking for high output and precision, the best automatic piston filling machine offers both speed and long-term dependability. Its versatility explains why piston filling machines are often considered the backbone of modern liquid packaging lines.

Key Benefits of Piston Fillers

Efficiency and Reduced Waste

One of the greatest strengths of a piston filler is its efficiency. Compared to manual filling, it operates faster and with less spillage, cutting down on wasted product. Over time, these savings translate into improved profitability. Efficiency also extends to labor: fewer staff are needed for manual filling tasks, which means operators can be reassigned to quality checks or higher-value activities. This creates leaner, smarter workflows that lower costs while maintaining output.

Consistency in Every Fill

Uniformity is critical for consumer trust, and piston filling machines excel at delivering consistency. By using a fixed cylinder volume, every container is filled with the exact same amount, ensuring compliance with packaging standards and enhancing brand reputation. Consistency also reduces complaints, returns, or compliance issues tied to underfilled or overfilled containers. In highly regulated industries such as pharmaceuticals or food production, this reliability can prevent fines and protect brand credibility.

Speed for Scaling Production

As demand grows, speed becomes essential. High-output models like the automatic piston filling machine or even a rotary piston filling machine can fill thousands of containers per hour. This scalability allows businesses to expand without compromising on quality or efficiency. A fast piston liquid filling machine ensures that production can keep pace with marketing pushes, seasonal spikes, or large distribution contracts. Instead of worrying about bottlenecks, companies can focus on meeting customer demand confidently.

Why Piston Fillers Outperform Alternatives

Compared to gravity or pump fillers, a volumetric piston filler is more versatile and reliable. While gravity systems work for free-flowing liquids, piston-based systems handle a wider range of viscosities, from thin oils to dense creams. A piston pump filling machine or piston liquid filling machine also tends to have a longer service life, reducing the total cost of ownership. When consistency and durability are non-negotiable, piston technology is the smarter long-term choice.

Choosing the Right Piston Filler for Your Needs

Not every production line requires the same type of filler. For small batches or startups, a semi-automatic piston filling machine may be sufficient. Larger facilities often benefit from integrating an automatic filling machine or a piston liquid filling machine that supports continuous, high-volume runs. Factors like container size, product viscosity, and target output all play a role in selecting the right equipment. Working with experienced suppliers ensures the chosen filler matches both current needs and future growth.

How Piston Fillers Support Overall Production Flow

Beyond speed and precision, piston fillers integrate seamlessly with other equipment such as cappers, conveyors, and labelers. This makes them essential for reducing downtime and ensuring a smooth workflow across the packaging line. A piston liquid filling machine not only boosts throughput but also supports quality control, helping companies meet deadlines and scale with confidence.

Conclusion

Investing in a piston filler is about more than just filling containers—it’s about efficiency, consistency, and the ability to grow without bottlenecks. With options ranging from semi-automatic to high-speed automatic piston filling machines, businesses can choose the solution that fits their goals. In an industry where precision and speed define success, piston technology stands out as one of the smartest investments a manufacturer can make.