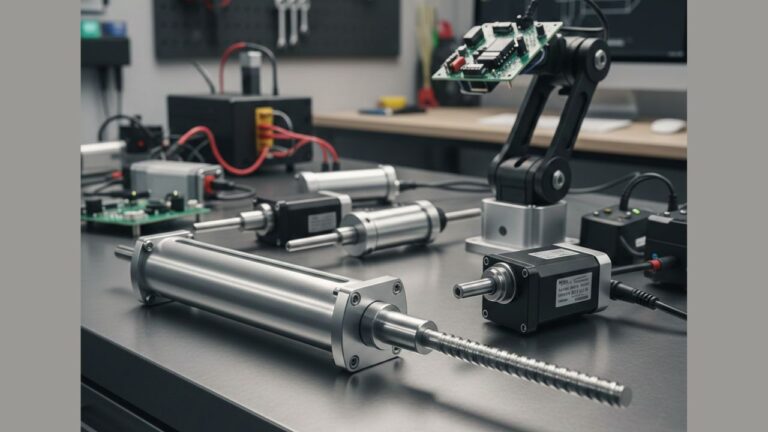

Automation often gets described with big ideas, but most real improvements come from small choices that make equipment behave more predictably. Motion control is one of those choices. When a system can open, close, lift, tilt, or position with consistent travel, daily operation tends to feel calmer. Fewer adjustments are needed. Fewer parts get forced into place. Maintenance turns into a regular habit instead of an unexpected issue. Linear actuators support that approach because they provide straight-line movement in a compact package that fits into many designs, from building systems to light industrial equipment. For an eco-minded audience, the value sits in practicality. Repeatable motion can reduce unnecessary wear, limit misalignment that leads to rework, and support longer service life by keeping mechanical stress closer to what the design intended.

Why Linear Motion Matters in Modern Automation

Many automation tasks need a precise start and stop rather than continuous rotation. A damper should move to a stable position. A service hatch should close firmly every time. A cover should lift without swinging into cables and sensors. Linear motion is useful in those scenarios because the travel path is defined. Instead of moving through an arc, the mechanism moves along a guided line, which makes it easier to manage clearances and avoid collisions inside compact enclosures. That matters when modern systems get denser. Controls, wiring, sensors, and structural elements all share limited space.

Linear actuators also fit well when the goal is repeatability across cycles. A motion path that returns to the same endpoints helps operators trust the equipment. It also supports easier troubleshooting. When a system behaves consistently, problems stand out faster. When it behaves differently each time, diagnosing an issue becomes guesswork. For facilities and integrators trying to keep systems stable over long periods, straight-line control can be a practical building block that improves the feel of operation without demanding an overly complex redesign.

Selecting an Actuator Without Overbuilding the System

For many system designers,https://www.progressiveautomations.com/en-eu/collections/linear-actuators becomes a practical reference when comparing configurations and understanding what “right-sized” motion looks like for different applications. The selection process works best when it starts with the motion task. Stroke length defines how far the mechanism must travel. Load planning should include not only the weight being moved, but also friction, seal resistance, and any side forces created by the geometry. Speed is another factor, yet it should fit the use case rather than chase quick movement for its own sake. Some applications benefit from faster travel, especially when exposure to weather or process timing matters. Other applications perform better with calmer movement that avoids jolts and keeps brackets from flexing.

Mounting style often decides whether the motion stays smooth. A rigid mount paired with shifting angles can create binding. Pivot points and proper alignment keep travel clean through the full range. Duty expectations also matter. A device that moves occasionally can be planned differently from one that cycles throughout the day. Environmental conditions shape choices as well. Dust, moisture, vibration, and temperature swings can turn a “fine on the bench” setup into a frustrating one in real use. The goal is not to overspec everything. The goal is to match the actuator to the actual job so the system stays predictable and serviceable.

Common Applications That Benefit From Straight-Line Control

Linear actuators appear in many places that an eco-focused reader will recognize, even when the actuator itself is hidden. Building ventilation is a clear example. Louvers and dampers need controlled positioning to manage airflow without constant manual intervention. Access panels and service hatches are another. A panel that opens smoothly and closes securely supports routine inspections and reduces the tendency to force hardware. Adjustable work surfaces and stations are also common in facilities that want better ergonomics without bulky mechanical solutions. A stable height change can make repetitive tasks easier while keeping the footprint compact.

In light industrial and processing spaces, linear motion can support covers, guards, and guided components that protect equipment while keeping access practical. In agriculture and greenhouse environments, straight-line motion can help with vents, shade control, and protective elements where compact integration matters. The shared thread is not a flashy automation story. It is a controlled movement that supports routine operation and keeps systems usable under everyday conditions.

Integration Details That Keep Motion Reliable Over Time

Even a well-chosen actuator can feel unreliable if integration is treated as an afterthought. Alignment is a practical example. If the actuator pushes at an angle that shifts during travel, binding can develop. That creates uneven motion and adds stress on mounts. A rigid, well-aligned structure helps the actuator do its job without fighting the mechanism. Cable routing is another essential detail. Moving parts and cables do not mix well unless the route is planned. Wiring should avoid pinch points and abrasive edges. Strain relief should protect connectors from being tugged during movement. Controls should also fit the workflow. If accidental activation is a realistic risk, control placement should reduce it. Service access matters too. An actuator that can only be reached by dismantling half a unit turns small adjustments into major interruptions.

Environmental protection should be considered early. Dust and moisture can build up in places that are hard to clean. Temperature shifts can change clearances. A design that leaves room for real-world conditions tends to stay stable longer. The result is a motion system that behaves consistently, which is often the most valuable outcome for daily operations.

A Practical Motion-Control Checklist for Cleaner Builds

A short checklist can keep motion upgrades grounded and prevent avoidable issues after installation. These points help translate a good concept into hardware that works the same way over time.

- Define the exact action the actuator will perform, including endpoints and stop positions.

- Confirm clearances through the full travel path, including cable bend radius and nearby hardware.

- Choose stroke length and load margin that account for friction, seals, and real-world resistance.

- Plan mounting geometry that stays aligned and avoids binding under load.

- Route cables with protection and strain relief, away from pinch points and sharp edges.

- Test movement under real load and in the intended orientation, not only on a workbench.

- Keep service access practical so adjustments can be made without major disassembly.

Motion That Supports Efficiency Without Noise

Automation can be modest and still be meaningful. A linear actuator selected with the actual task in mind can support calmer operation, fewer stop-start fixes, and more predictable maintenance. That fits sustainability goals in a practical way because equipment that runs smoothly is easier to keep in service and easier to maintain without constant improvisation. Thoughtful motion control also helps systems stay organized. Clear travel paths, stable stops, and clean integration reduce the small mechanical frustrations that build over time.

When comparing actuator configurations for automation and motion control, the Progressive Automations collection referenced earlier can serve as a neutral point of orientation for strokes, mounting styles, and application fit. The real takeaway is simple. Straight-line motion, planned with alignment, environment, and service access in mind, can make equipment behave more consistently in the places where consistency matters most.

READ ALSO: Why Your Competitor’s Proposal Looks Better Than Yours (And How to Change That)