In the competitive industrial world, companies are constantly under pressure to ensure the durability, performance, and reliability of instruments and their components.

Whether it is electronics that need to conduct electricity without failure or medical equipment in which precision and safety are paramount, even a slight compromise can cost a lot.

Corrosion, wear, or unreliable conductivity are frequent problems for manufacturers, with a direct effect on product quality and efficiency.

These difficulties can lead to frequent replacements, downtime, and high maintenance expenses.

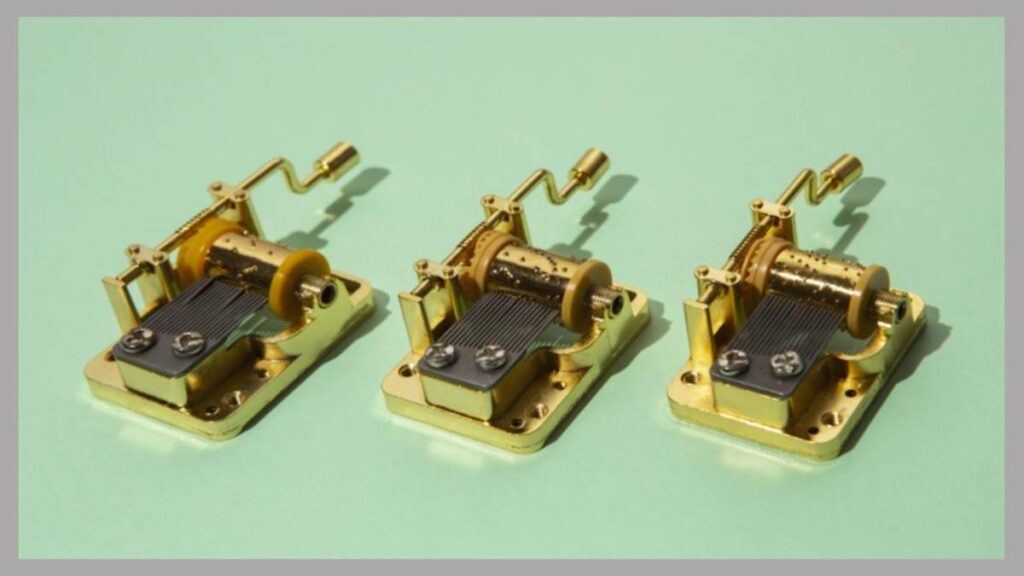

Professional gold plating can be a viable solution, providing a gold coating over parts to improve usability and longevity.

This article discusses the significant advantages of professional gold plating services across industries and how this process helps address serious operational challenges.

1. Enhanced Corrosion Protection

Corrosion affects a significant number of valuable instruments and their components that encounter humidity, chemicals, or temperature changes, and can quickly wear them out, affecting performance and safety.

Professional gold platers offer gold plating services that provide resistance to oxidation and wear. Gold’s chemical inertness also prevents components from degrading even under extreme conditions. This is especially true with connector pins, electrical contacts, and other devices in the oil and gas or telecommunications industries.

Gold plating extends the life of parts by preventing corrosion, reducing replacement costs, and ensuring consistent performance under severe conditions.

2. Superior Electrical Conductivity

In the electronics, semiconductor, and energy technology industries, they cannot compromise on high-end electrical conductivity. Gold is a great conductor, and its resistance does not change with time.

Electrical components that undergo frequent electrical cycling, such as switches and connectors, benefit significantly from gold plating. The process ensures minimal signal loss, minimizes the risk of short-circuiting, and maintains operational accuracy.

In addition, gold plating improves solderability in applications where other metals may fail, increasing manufacturing speed and product lifespan. Gold plating is essential to industries that rely on continuous electrical performance.

3. Increased Water Resistance And Durability

The friction and mechanical wear may affect the functionality of vital parts.

Gold plating makes metals, particularly when used in an alloy, more rigid and more resistant to wear. This increases the strength of components under repetitive mechanical contact and enhances their lifespan.

Repeated sterilization and reuse can damage the surfaces of medical and dental tools over time.

Gold-plating solves this issue, allowing parts to retain their smoothness, be less prone to scratching, and deliver consistent performance, ensuring that high-precision applications do not introduce inaccuracies.

4. Medical Biocompatibility And Safety

The medical and dental sectors expect materials to be not only helpful but also safe for human use.

Gold plating meets biocompatibility requirements, so manufacturers use it in implants, surgical instruments, and dental instruments. It is not reactive and minimizes the risk of allergic reactions, contamination, or tissue irritation.

Moreover, gold’s durability ensures the devices continue to work even after multiple sterilizations. In this way, professional gold plating services ensure patient safety and the lifespan of medical equipment, thereby promoting psychomotor composure among practitioners and patients

5. Precision In Semiconductor And Electronics Manufacturing

Precision is all in the high-tech industry, particularly in semiconductors and electronics. Even the slightest microscopic flaws on component surfaces may affect performance.

Gold plating enables the manufacturing company to achieve uniform, ultra-thin layers that preserve dimensional integrity and increase conductivity and reliability.

The step is essential for components used in microelectronics, high-frequency equipment, and thermocompression bonding, where even minor defects cause failures or reduced productivity.

Professional gold plating services help companies ensure that sensitive components are consistently maintained to the desired quality standard and that the risk of the manufacturing process leaving a blemish is kept to a minimum.

It also improves long-term operational stability, reduces maintenance requirements, and works with high-tech equipment that meets industry standards and high-quality control norms.

6. Cost-Effectiveness Over Time

Gold plating can seem like an expensive luxury service; however, it saves a lot in the long run.

It enhances corrosion and wear resistance and electrical performance, thereby necessitating less replacement, repair, and downtime.

The high costs for the energy, telecommunications, and oil and gas industries might arise from component failures that occur without prior warning.

That said, the risks may be minimized by engaging professional gold plating services that ensure efficient, high-performance components and lasting performance.

The initial investment in plating is soon outweighed by the long-term maintenance and operational interruptions, making it a very viable option for a business concerned with sustainability and reliability

Final Thoughts

Professional gold plating services can provide a tangible advantage in a large market segment. Gold plating solves the most challenging problems manufacturers face by increasing corrosion resistance, electrical conductivity, durability, biocompatibility, and overall perfection.

In addition to these technical benefits, it is also cost-effective, making it a wise investment for companies that value quality, performance, and reliability.

Whether in medical devices, electronics, or energy, gold plating ensures components meet high industry standards and deliver the best performance over time.